மின்னஞ்சல் வடிவமைப்பு பிழை

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

செய்திகள்

Which Industries Are the Machining Centers Suitable For

A machining center is a kind of CNC machine tool. From the literal point of view, the CNC machine tool mainly consists of two parts: the CNC device and the machine tool. It also needs to be equipped with necessary auxiliary devices, such as a tool magazine, indexing heads, manipulators, etc. The composition of CNC machine tools can be divided into parts: CNC system, machine main body, and transmission system. If you want to know which industries and fields the machining center is suitable for, you must know its structure and working principle. Let's explore it together!

CNC system

What is numerical control, as the name implies, refers to the numerical change of the control process. Numerical control is an automatic control technology developed in recent decades. It is a method of using digital signals to control the movement of a machine tool and its processing process, referred to as numerical control NC. The numerical control technology used in the machining center is controlled by a computer, which means that the numerical control device is a special computer control device, so it is also called computer numerical control, or CNC for short. Therefore, the machining center is also called cnc machining center.

The CNC system can be said to be the soul of the machining center. It is the basis for the entire machine tool to complete various functions and operations. Without the CNC system, the machining center is just a pile of scrap iron. The CNC system is mainly divided into two categories: one is the drive device, which includes a high-speed spindle and a motor. The other type is the control and detection device, including a CNC system, programmable controller, feed servo control module, position detection module, etc.

Machine body

The main component of the machining center, which can also be said to be the hardware of the machining center, is also the part that is easiest to see with the naked eye, including the body, base casting, spindle, variable box, guide rail, lubrication, cooling, and chip removal.

Transmission system

The transmission system is the "context" of the machining center, and it is the device that connects the various components of the machining center to work in an orderly manner, including tools, transmission machinery, and auxiliary force systems.

The tool includes a guard and a tool magazine. The disc magazine also has a robotic arm.

Transmission machinery is the second-largest component of the transmission system, including three parts: ball screw, linear guide, and worm pair.

The auxiliary power system is the power of the machining center, including the hydraulic system and the starting system.

What fields are machining centers suitable for?

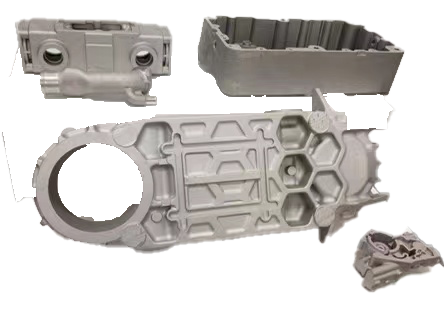

The applicable field of the machining center can reflect the full role of the machining center as a "mother machine". Take the vmc850 machining center as an example, as the most widely used machining center, it can realize the one-time clamping of various discs, plates, shells, cams, molds, and other complex parts, and can complete drilling, milling, boring, expanding, reaming. , rigid tapping and other processes. Machining centers are widely used in manufacturing and processing industries in general, including the following fields:

- Defense field: aerospace, ship industry, weapon manufacturing;

- Automotive field: body processing, cylinder block processing, transmission, clutch, shaft components, etc.;

- Life field: mobile phone metal shell, back cover, handicrafts, etc.;

- Industrial field: aluminum molds, copper molds, curved parts, etc.

Conclusion

For more information about high precision milling machine,table top milling machine cnc,used cnc vertical milling machine, we are glad to answer for you.