மின்னஞ்சல் வடிவமைப்பு பிழை

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

செய்திகள்

Analysis of Melting Process of Zinc Alloy Die Casting Raw Materials

Zinc alloy die casting melting furnace melting zinc ingot is a key step in the whole process of aluminum die-casting. The whole process of melting is not only to obtain a molten metal material liquid, but also to obtain components that meet the requirements. Zinc alloy die-casting can obtain excellent crystal structure and vapor. Appropriate zinc alloy die-casting process specification is the key to ensuring high-quality castings.

The best melting temperature for zinc alloy die casting:

The melting point of zinc alloy materials for aluminum die casting is 382~386 °C, and suitable temperature and temperature control is a key factor in the control of zinc alloy materials. In order to ensure the excellent fluidity of the aluminum alloy liquid to fill the die, the temperature of the metal material liquid in the zinc pot of the aluminum die-casting machine is 415~430 °C, and the temperature of the aluminum die-casting for thick-walled parts and complicated parts can be limited; thin-walled parts and simple parts can use the lower limit. The temperature of the metal material liquid in the central government smelting furnace is 430~450℃. The temperature of the molten metal entering the gooseneck is basically the same as the temperature in the zinc pot. The pouring temperature can be precisely controlled by controlling the temperature of the metal material in the zinc pot.

When the melting temperature is too high

The reaction between the iron tong pot and the zinc liquid is accelerated, and the surface of the tong pot produces an iron redox reaction to produce Fe2O3 and other metal oxides; iron-containing will continue to react with the zinc liquid and transform into FeZn13 chemical substances (zinc slag), which are dissolved in the zinc liquid. . Aluminum and magnesium elements are ablated, the air oxidation rate of metal materials is accelerated, the amount of ablation is increased, and the zinc slag is increased. The effect of thermal deformation can cause a stuck high-chromium alloy hammer. A large amount of iron is melted into the aluminum alloy in the pig iron tong pot, and the reaction between zinc and iron is accelerated at high temperatures. It will produce hard particles of chemical substances between iron-aluminum metal materials, which will cause excessive damage to the high-chromium alloy hammer head and gooseneck. A large amount of iron is melted into the aluminum alloy in the pig iron tong pot, and the reaction between zinc and iron is accelerated at high temperatures. It will produce hard particles of chemical substances between iron-aluminum metal materials, which will cause excessive damage to the high-chromium alloy hammer head and gooseneck. However, the cost of materials is relatively increased. The higher the temperature, the stronger the crystals of the castings and the reduced physical properties.

When the melting temperature is too low

the aluminum alloy has poor fluidity, which is not conducive to forming and endangers the technological performance of the casting.

How to keep the temperature steady

Today's aluminum die-casting machine melting pots or melting furnaces are equipped with temperature measurement and control systems, and inspections are performed regularly to ensure the accuracy of temperature measurement instruments. Portable thermometers (thermometers) are used to evaluate the specific temperature of the melting furnace on time and give calibration. The aluminum die-casting association with working experience observes the melt with human eyes. If the melt is not too thick and clear after scraping the slag, and the slag is not fast, it indicates that the temperature is suitable; if the melt is too thick, it indicates that the temperature is slightly Low; after scraping the slag, the liquid level quickly exudes a layer of white frost, and the slag is too fast, indicating that the temperature value is high, and it should be adjusted immediately. The best way is to use the central government melting furnace and the die-casting machine melting furnace as the holding furnace, so as to prevent the large temperature change when the zinc ingot is immediately added to the zinc pot for melting. Centralized smelting can ensure the stability of aluminum alloy composition. Or choose the excellent automatic feeding system software of metal material liquid, which can maintain the feeding rate, the temperature of aluminum alloy liquid and the aspect ratio of zinc pot liquid level for a long time. If the zinc pot is charged immediately, it is proposed to change the one-time addition of a single aluminum alloy ingot to adding a small aluminum alloy ingot several times, which can reduce the temperature change caused by the feeding.

Manipulation of Zinc Slag

According to the molten aluminum alloy from solid to liquid, it is a complicated whole process of physics and organic chemistry. The vapor and the molten metal material produce chemical changes, in which the reflection of oxygen is more obvious, and the surface layer of the aluminum alloy is oxidized to cause a certain amount of sludge. The sludge contains metal oxides and chemical substances between iron, zinc and aluminum metal materials, and the sludge scraped from the surface of the solution generally contains about 90% of zinc alloy materials. The reaction time of zinc slag increases exponentially with the increase in smelting temperature. Under all normal conditions, the slag production of the initial zinc alloy material ingot is less than 1%, which is in the range of 0.3~0.5%; while the slag production in the remelting water part and the waste product workpiece is generally between 2% and 5%.

Conclusion

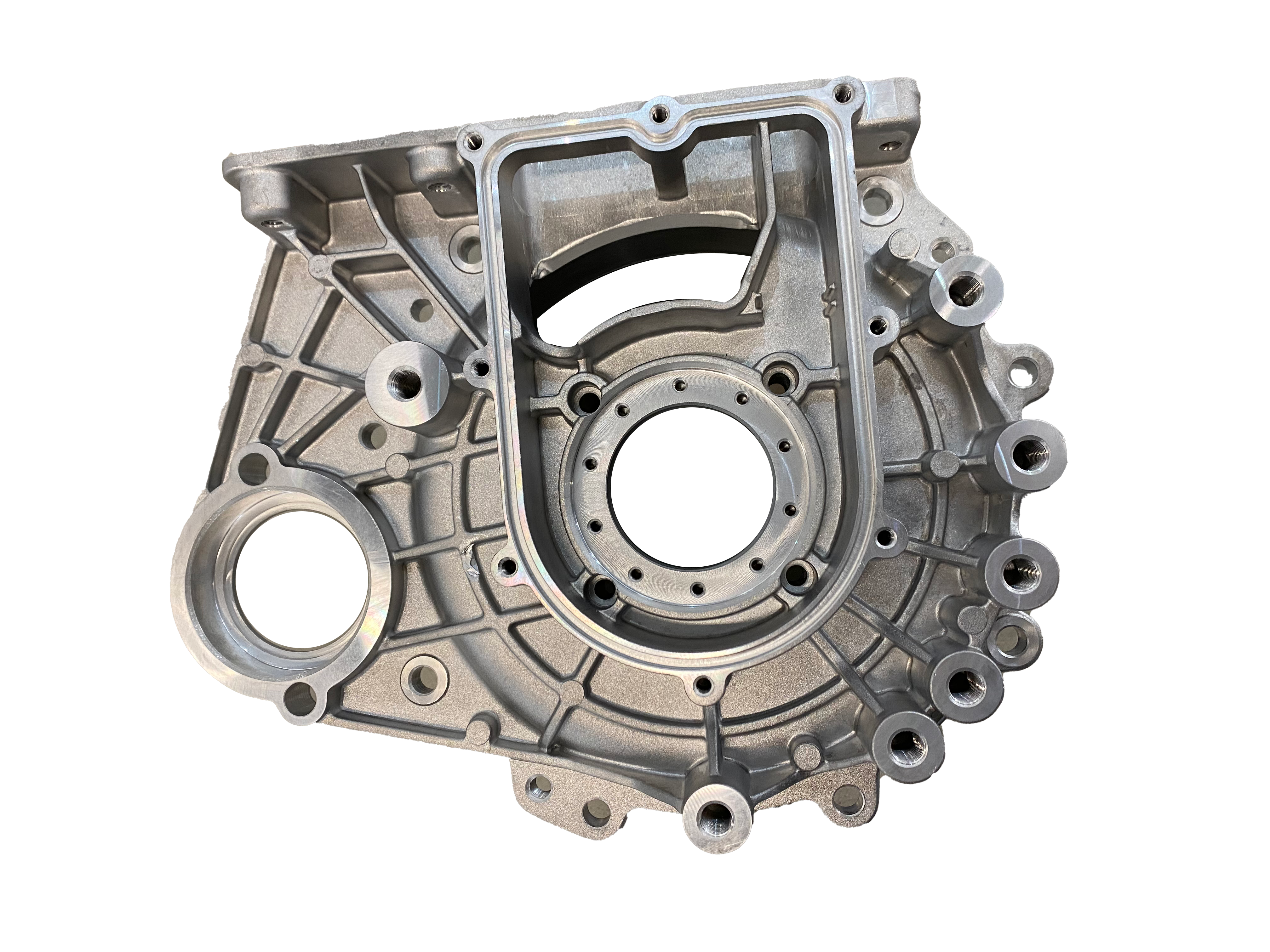

For more information about pressure die casting aluminium alloys,die casting automotive,die casting machine process, we are glad to answer for you.